What Is The Advantages of Horizontal Milling?

What Is The Advantages of Horizontal Milling?

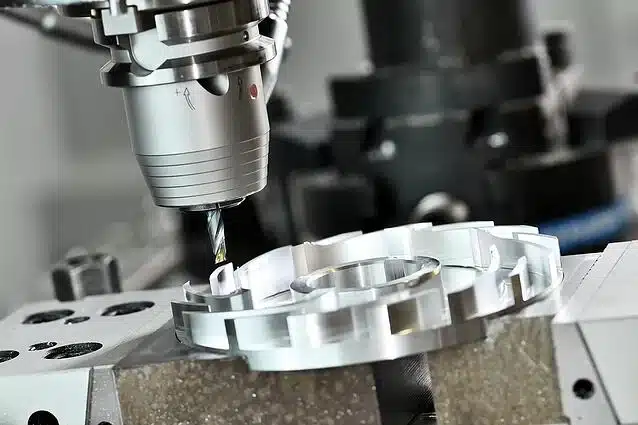

Horizontal milling is a machining process in which a cutting tool is mounted on a spindle that is horizontal to the workpiece. The cutting tool can be moved across the face of the workpiece, taking small chips or “cuts” as it moves.

As a prototyping manufacturer, WayKen also uses this type of milling machine to create flat surfaces or to remove material from the workpiece quickly and efficiently. Horizontal milling can also be used to create angled or tapered surfaces, depending on the type of cutting tool that is being used.

The advantages of horizontal milling over other methods

Horizontal milling offers several advantages over other milling methods:

1) Increased productivity – Horizontal milling machines can handle larger workloads than vertical milling machines, since they are designed to have a higher production capacity.

2) Greater versatility – Horizontal milling machines can be equipped with a wider range of tooling than vertical milling machines, allowing them to perform a greater variety of machining operations.

3) improved accuracy – Horizontal milling machines generally offer more accurate positioning than vertical milling machines, making them ideal for precision machining applications.

4) easier chip removal – Since horizontal milling machines cut along the horizontal plane, chips are ejected more easily and do not tend to build up on the workpiece, as they can with vertical milling machines.

5) Reduced operator fatigue – Horizontal milling machines require less operator input than vertical milling machines, resulting in reduced operator fatigue.

The above are just a few of the advantages that horizontal milling machines offer over other milling methods. If you are considering purchasing a milling machine, be sure to consider a horizontal model to take full advantage of these benefits.

How horizontal milling can be used to create large, flat surfaces

Horizontal milling is an ideal method for creating large, flat surfaces. The cutting tools on a horizontal milling machine are able to move in a wide range of directions, allowing them to create very large, flat surfaces with a high degree of accuracy. Additionally, the operator of a horizontal milling machine can see the workpiece more easily than with a vertical milling machine, making it easier to keep the cutting tools on track.

How horizontal milling can be used to remove material quickly and efficiently

Horizontal milling is a great way to remove material quickly and efficiently. It can be used to remove large amounts of material at a time, making it a very efficient method for removing material. Horizontal milling can also be used to remove small amounts of material, making it a very versatile method for removing material.

The different types of surfaces that can be created with horizontal milling

Horizontal milling allows for a wide range of surface textures to be created, due to the different types of milling cutters that can be used. For example, a roughing cutter can be used to create a textured surface, while a finishing cutter can create a smooth surface. Additionally, horizontal milling can be used to create complex surface textures, such as those with swirls or other patterns.

Why horizontal milling is the preferred method for many machining applications

There are many reasons why horizontal milling is the preferred method for many machining applications. One of the most important reasons is that it allows for more accurate and precise cuts. When cutting metal, accuracy is key in order to create products that function correctly and look good.

If a cut is even slightly off, it can throw the whole piece off, and cause problems down the line. With horizontal milling, the accuracy is much higher, since the cutting tools are more in line with the workpiece.

Another reason why horizontal milling is so popular is that it tends to be faster than vertical milling. This is because the cutting tools are able to move along the length of the workpiece more quickly. This is especially helpful when working with large pieces, or when time is of the essence.

Finally, horizontal milling generally results in a smoother finish. This is because the cutting tools are able to move in a single direction, rather than having to go back and forth. This results in a cleaner cut, and a smoother surface.

Conclusion

Overall, horizontal milling offers a number of advantages over other milling methods, including the ability to create a wide range of surface textures and the ability to produce complex shapes. Additionally, horizontal milling is generally more efficient than other methods, making it a good choice for high-volume applications.

Lucas Noah is a tech-savvy writer with a solid academic foundation, holding a Bachelor of Information Technology (BIT) degree. His expertise in the IT field has paved the way for a flourishing writing career, where he currently contributes to the online presence... Read more