Precision And Complexity: Advancements In 5-Axis Cnc Machining For Auto Engine Components

Precision And Complexity: Advancements In 5-Axis Cnc Machining For Auto Engine Components

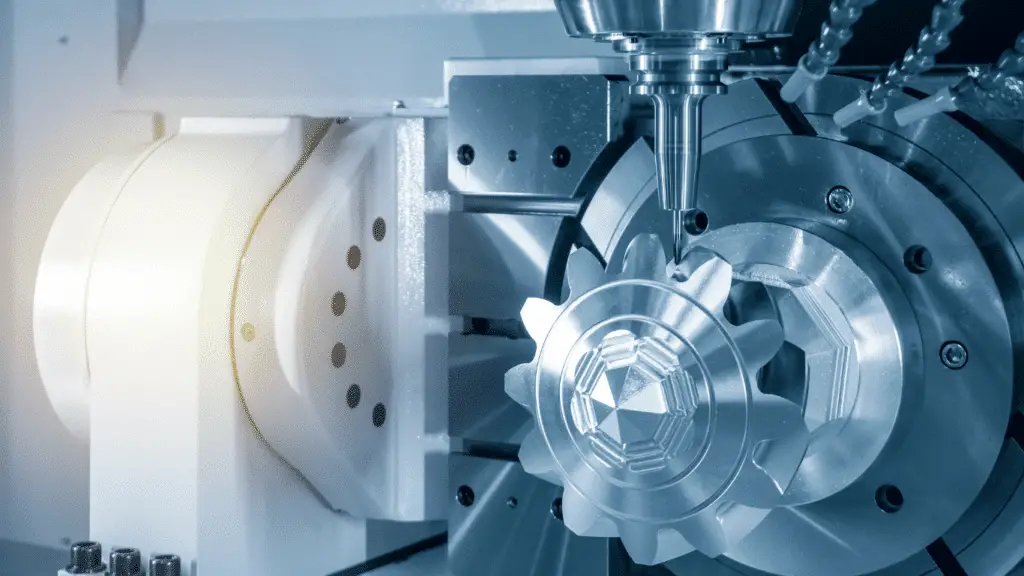

The production of auto engine components has been redefined by improvements in 5-axis CNC machining, which provide unmatched precision and the capacity to handle complex geometries. Due to the finer tolerances made possible by this technology, engine performance, efficiency, and reliability have all improved. keep reading this article to learn more about 5-axis CNC machining, its benefits, and applications.

What’s 5-Axis CNC Machining?

5-axis CNC machining is the movement of a cutting tool along five separate axes using a computer numerical control (CNC) system. X, Y, and Z are the only three axes employed in classical machining, which restricts tool movement and shapes’ complexity. But with 5-axis CNC machining services, two extra rotational axes are added, enabling the cutting tool to operate in a variety of directions and angles at once.

X, Y, Z, A, and B are the five axes of this high precision technique. Linear motions are represented by the X, Y, and Z axes in the horizontal, vertical, and depth dimensions. A and B axes allow rotational motions around X and Y axes, respectively, to access different angles and features on a workpiece.

Manufacturers can produce extremely complicated and sophisticated components with higher precision and accuracy by using 5-axis CNC machining, which incorporates two extra axes of motion. This method is very useful for creating parts with complex geometries, curved surfaces, undercuts, and features that need to be simultaneously machined from various angles. During the production of auto engine parts and other precision parts, it usually delivers increased productivity, decreased setup time, and higher overall quality.

Benefits of 5-Axis CNC Machining for Auto Engine Manufacturing

The capacity to handle complicated geometries, increased flexibility and efficiency, and higher accuracy and precision are just a few benefits that 5-axis CNC machining offers the auto engine production industry. Let’s examine these benefits in more detail:

- Improved accuracy and precision: It allows manufacturers to produce auto engine components with a higher degree of accuracy and precision. Tighter tolerances and consistent quality throughout production runs are made possible by the additional axes of movement, which also provide control and diversity in tool positioning. This level of accuracy is essential for auto engines since even little variations can have a big influence on reliability and performance.

- Enhanced flexibility and efficiency: Its multi-axis capacity increases the manufacturing process’s adaptability and productivity. Since the machine can reach different angles and features without relocating the part, the need for several setups is avoided. As a result, the production process is streamlined, setup time is cut down, and the risk of mistakes brought on by manual repositioning is decreased. The increased flexibility also makes it possible to machine intricate features and undercuts that would be difficult or impossible to accomplish with conventional machining techniques.

- Complex geometry capabilities: One of the most notable features of 5-axis CNC machining for automotive parts is its simplicity in handling complex geometries. To maximize performance, auto engine components frequently need complex geometries, curved surfaces, and fine details. The cutting tool is able to accurately grasp and produce these intricate shapes because of the simultaneous movement of numerous axes. This capacity creates new design opportunities and makes it possible to produce cutting-edge engine components that offer improved performance and efficiency.

Applications of 5-Axis Machined Auto Engine Components

In the automotive industry, 5-axis machined components find applications across many critical engine parts. Examples include:

- Cylinder heads: Cylinder heads are essential to an engine’s combustion process. They house the combustion chambers, valves, and intake and exhaust ports. With the use of 5-Axis machining, complicated geometries of cylinder heads may be precisely shaped and machined, resulting in the best possible airflow, combustion efficiency, and power output. It is possible to precisely mill the delicate shapes and channels found within the cylinder heads, improving performance and lowering emissions.

- Engine blocks: This is the engine’s main structural component, that houses the engine’s cylinders, crankshaft, pistons, and other essential parts. Engine blocks with complicated coolant passageways, oil galleries, and precise mating surfaces can be created using 5-axis machining. By ensuring appropriate coolant and oil circulation, improved structural integrity, and effective power transmission, this precision machining improves the engine’s overall durability and performance.

- Valvetrain components: The valvetrain is made up of parts that control the operation of the intake and exhaust valves, including camshafts, valves, lifters, and rocker arms. With the use of 5-axis machining, complicated lobed camshafts, finely machined valve seats and surfaces, and elaborate lifter designs may all be produced. With such accuracy, enhanced engine performance, effective airflow, and ideal valve timing are all guaranteed.

Auto engine manufacturers can produce vital parts with complicated designs and exact tolerances using 5-axis CNC machining, leading to engines that offer higher performance, increased fuel efficiency, and less emissions. The construction of more potent and dependable engines is eventually aided by the improved capabilities of 5-axis machining, which enable the optimization of airflow, combustion, and overall engine efficiency.

Lucas Noah is a tech-savvy writer with a solid academic foundation, holding a Bachelor of Information Technology (BIT) degree. His expertise in the IT field has paved the way for a flourishing writing career, where he currently contributes to the online presence... Read more