Mastering the Puzzle: How Box Build Assembly Fits the Pieces Together

Box Build Assembly

Box build assembly is a crucial process that brings together various components, technologies, and expertise to create a fully functional electronic or mechanical product. From intricate circuitry to mechanical components and packaging, box build assembly plays a vital role in the manufacturing and assembly of a wide range of products.

Introduction to Box Build Assembly

Box build assembly, also known as system integration or turnkey assembly, involves the complete assembly of a product within an enclosure or “box.” It encompasses the integration of electrical and mechanical components, wiring and cabling, connectors and interfaces, and the final packaging of the product. The aim of box build assembly is to create a finished product that is ready for use or installation, saving time and effort for the end-user.

Understanding the Components of Box Build Assembly

The Importance of Box Build Assembly

Box build assembly serves as the cornerstone of many industries, including automotive, aerospace, telecommunications, consumer electronics, and medical devices. It brings together a diverse range of components to create products that are reliable, functional, and aesthetically appealing. Without box build assembly, the intricate pieces of the puzzle would remain separate and disjointed.

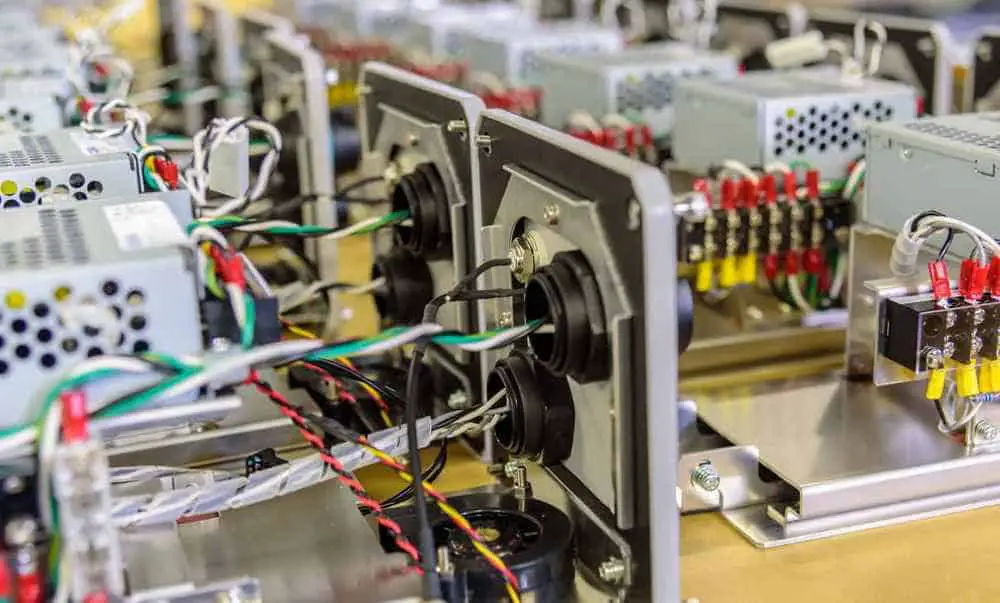

Electrical Components

In box build assembly, electrical components such as printed circuit boards (PCBs), resistors, capacitors, integrated circuits, and power supplies are carefully integrated and interconnected. The electrical components ensure the proper functioning of the product, enabling functionalities such as power distribution, data transmission, and signal processing.

Mechanical Components

Alongside electrical components, mechanical parts are crucial in box build assembly. These components include chassis, frames, brackets, fasteners, and other hardware elements that provide structural integrity and support for the electronic components. Mechanical components ensure that the product is robust, durable, and capable of withstanding various environmental conditions.

Wiring and Cabling

The interconnection of electrical components is facilitated by wiring and cabling. Cables, connectors, and harnesses are carefully selected and integrated to ensure proper signal transmission, power distribution, and compatibility between different components. The wiring and cabling process requires meticulous attention to detail and adherence to industry standards.

Connectors and Interfaces

Connectors and interfaces play a vital role in enabling seamless connections between various components. These include USB ports, HDMI ports, audio jacks, and other interfaces that allow users to interact with the product. Proper selection and integration of connectors and interfaces ensure compatibility and ease of use.

Enclosures and Packaging

The final piece of the box build assembly puzzle is the enclosure and packaging. This involves selecting the appropriate housing or casing for the product, considering factors such as aesthetics, functionality, and environmental protection. Enclosures not only provide physical protection but also contribute to the overall design and branding of the product.

Common Challenges in Box Build Assembly

While box build assembly manufactured by pcb assembly manufacturer offers numerous advantages, it is not without its challenges. Let’s explore some common challenges:

Complex Project Management

Box build assembly projects often involve numerous stakeholders, including design engineers, procurement teams, assembly technicians, and quality control personnel. Coordinating these diverse teams and managing their inputs can be complex. Effective project management, clear communication, and collaboration are essential to ensure all project milestones are met.

Integration Issues

Integrating different electrical and mechanical components can present compatibility challenges. Ensuring proper fitment, alignment, and interconnections can be time-consuming and require technical expertise. Thorough testing and prototyping help identify and address integration issues early in the process, minimizing rework and delays.

Compatibility Challenges

Box build assembly may involve integrating components from multiple suppliers. Ensuring compatibility between these components, such as connectors, interfaces, and software, can be challenging. Close collaboration with component suppliers and adherence to industry standards can mitigate compatibility issues.

Regulatory Compliance

Different industries have specific regulations and compliance standards that products must meet. Box build assembly processes need to align with these regulations, such as safety standards, electromagnetic compatibility (EMC), and environmental requirements. Adhering to these regulations ensures that the final product meets industry standards and avoids any legal or compliance issues.

Scalability and Flexibility

Box build assembly processes need to accommodate scalability and flexibility. As products evolve and demand fluctuates, manufacturers should be able to scale production volumes and adapt assembly processes accordingly. This requires a robust supply chain, agile manufacturing capabilities, and flexible assembly lines.

Best Practices for Successful Box Build Assembly

To ensure successful box build assembly, consider the following best practices:

Collaboration and Communication

Clear and effective communication among all stakeholders is essential. Regular meetings, progress updates, and sharing of information help align expectations and address any issues promptly. Collaboration between design engineers, procurement teams, and assembly technicians ensures a smooth assembly process.

Thorough Planning and Documentation

Invest time in thorough planning and documentation. Create detailed assembly plans, bill of materials (BOMs), and assembly instructions. These documents serve as a reference for assembly technicians and ensure consistency and accuracy throughout the process.

Quality Management Systems

Implement robust quality management systems to ensure the highest quality standards. This includes defining quality control checkpoints, conducting comprehensive testing at various stages, and continuously monitoring and improving the assembly process.

Streamlining the Supply Chain

Establish strong relationships with trusted suppliers to streamline the supply chain. Maintain a reliable supply of components and materials to avoid delays and disruptions. Consider partnering with a contract manufacturer who has established relationships with suppliers and can leverage economies of scale.

Continuous Improvement and Adaptability

Embrace a culture of continuous improvement and adaptability. Regularly evaluate the assembly process, identify areas for optimization, and implement changes accordingly. Stay updated with industry trends, technologies, and regulations to ensure the box build assembly process remains efficient and compliant.

Conclusion

Box build assembly is the process that brings together the intricate pieces of a product, fitting them together like a puzzle. With its focus on integration, testing, and packaging, box build assembly plays a vital role in the manufacturing of various electronic and mechanical products. By understanding the components, process, advantages, challenges, and best practices associated with box build assembly, manufacturers can streamline their operations, deliver high-quality products, and meet the demands of today’s dynamic markets.

FAQs

What is Box Build Assembly?

Box build assembly is the process of integrating electrical and mechanical components, wiring, connectors, and interfaces within an enclosure or “box” to create a fully functional product.

What industries benefit from Box Build Assembly?

Industries such as automotive, aerospace, telecommunications, consumer electronics, and medical devices benefit from box build assembly.

How does Box Build Assembly differ from PCB assembly?

While PCB assembly focuses on the assembly of printed circuit boards, box build assembly involves the integration of PCBs along with other electrical and mechanical components within an enclosure.

What is the role of a contract manufacturer in Box Build Assembly?

Contract manufacturers specialize in box build assembly, providing end-to-end solutions for product assembly, integration, testing, and packaging. They leverage their expertise and resources to ensure efficient and high-quality assembly processes.

How can companies ensure quality control in Box Build Assembly?

Companies can ensure quality control in box build assembly by partnering with reputable contract manufacturers who have stringent quality management systems in place. Additionally, comprehensive testing, adherence to industry standards, and continuous improvement efforts contribute to maintaining quality standards.